- Years Of

- Working Experience

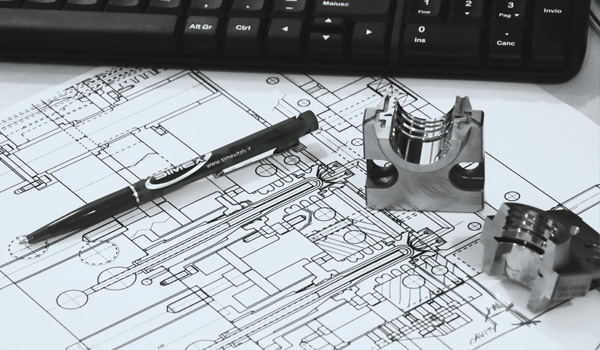

After years of careful research, we have developed a set of independent self-locking preform molds. The needle-valve preform molds have been widely used in edible oil, beverages, candy, cosmetics, pesticides, medicine and many other packaging industries. , With its high-quality, high-efficiency, energy-saving, and long-life characteristics, it sells well at home and abroad, and has been praised by users. It is exported to the United States, Europe, South America, the Middle East, Southeast Asia, Africa and other countries and regions, and sales have increased steadily year by year.

Make high-quality PET molds for you with your heart

1. Product research

Bitop Mould can conduct performance research according to the type of container destination in its company's planning and manufacturing department, so the following factors should be considered: 1. Stretch/blow ratio 2. weight 3. Wall thickness 4. Length of performance 5. Completion type 6. End use

2. Injection mold engineering

Because its technical office is equipped with an advanced CAD/CAM system, Bitop Mould is able to project injection molds from 1 to 144 cavities according to the latest technical standards to achieve high quality and complete the final product in the shortest manufacturing time. Production of products.

3. Assistance and after-sales service

Bitop’s technical staff can use it for customers: • At the beginning of the project, inspections by the customer for technical discussions and possible measurements •Through our senior professional and technical personnel to provide assistance in the inspection and testing of production molds •After-sale assistance throughout the warranty period