Professional PET mold manufacturing expert

BITOP Mould has been working in the field of "PET preform mould packaging" for more than 20 years, providing customers with its own experience and expertise for the production of preforms and preform moulds and equipment. Over the years, BITOP has designed hundreds of different PET preform molds. Whether you need basic molds or complex molds, we have the skills and experience to design molds accurately and on time.

ABOUT US

Bitop, located in Huangyan, a well-known mold town, is an enterprise specializing in the development and production of preform molds, which can be customized according to customer requirements. High satisfaction, preferential prices and quality assurance. After years of careful research, we have developed a set of independent self-locking structure preform molds. The needle-valve structure preform molds have been widely used in edible oil, beverages, candy, cosmetics, pesticides, medicine and many other packaging industries. High-quality, high-efficiency, energy-saving, and long service life are sold well at home and abroad, and have been praised by users. They are exported to the United States, Europe, South America, the Middle East, Southeast Asia, Africa and other countries and regions, and sales have been steadily increasing year by year.

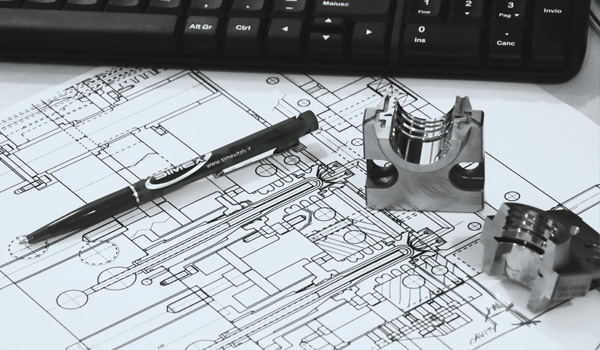

We have advanced mold processing equipment, strong technical force, fully adopt CAD/CAE/CAM system for the design, modeling and programming of various preform molds, and have the ability to manufacture high, precise and sharp molds. ability. In the design, we all use CAD, 2D&, 3D and other software technologies to meet the needs of various shape designs of plastic products in the market today.

Bitop Mould promotes the entrepreneurial tenet of "treating people with sincerity and trustworthiness", and pursues the policy of "zero failure in quality, customer satisfaction", to achieve stable quality, timely delivery, reasonable prices, and thoughtful service. Customers are assured and satisfied. Warmly welcome new and old customers at home and abroad to visit and negotiate!

Make high-quality PET molds for you with your heart

1. Product research

Bitop Mould can conduct performance research according to the type of container destination in its company's planning and manufacturing department, so the following factors should be considered: 1. Stretch/blow ratio 2. weight 3. Wall thickness 4. Length of performance 5. Completion type 6. End use

2. Injection mold engineering

Because its technical office is equipped with an advanced CAD/CAM system, Bitop Mould is able to project injection molds from 1 to 144 cavities according to the latest technical standards to achieve high quality and complete the final product in the shortest manufacturing time. Production of products.

3. Assistance and after-sales service

Bitop’s technical staff can use it for customers: • At the beginning of the project, inspections by the customer for technical discussions and possible measurements •Through our senior professional and technical personnel to provide assistance in the inspection and testing of production molds •After-sale assistance throughout the warranty period