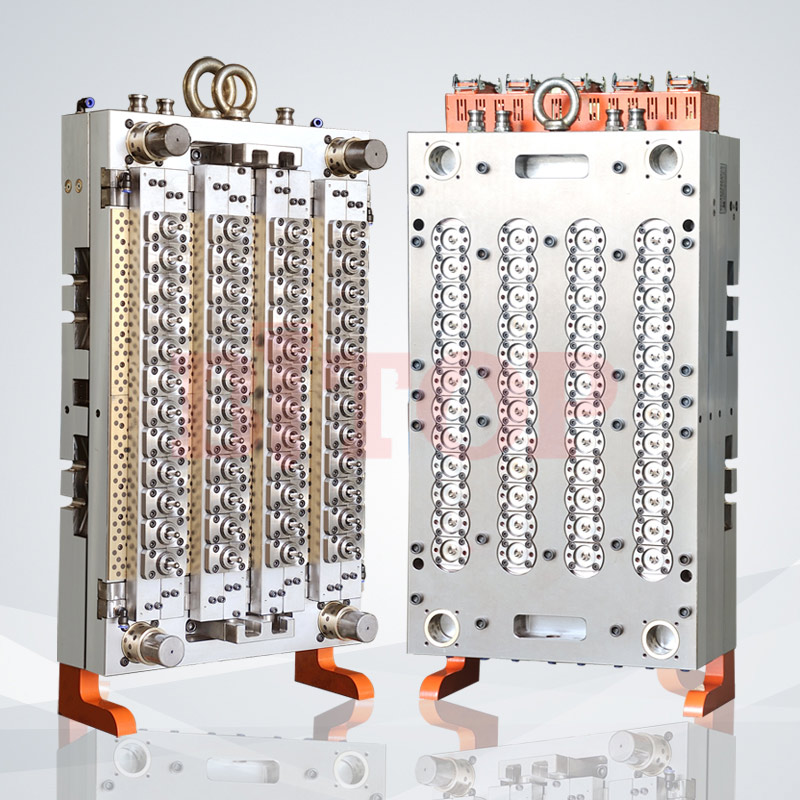

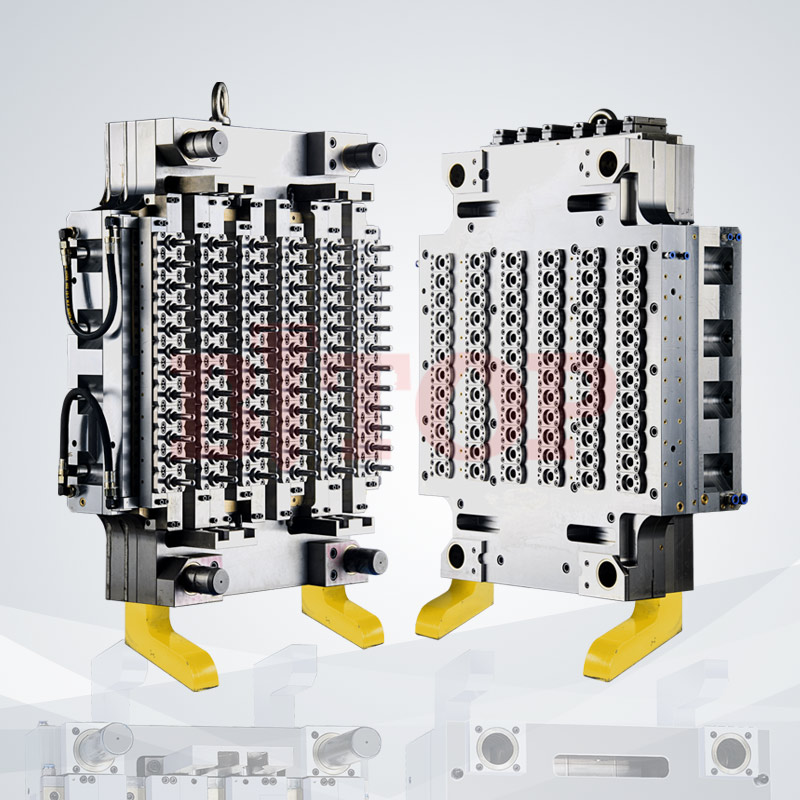

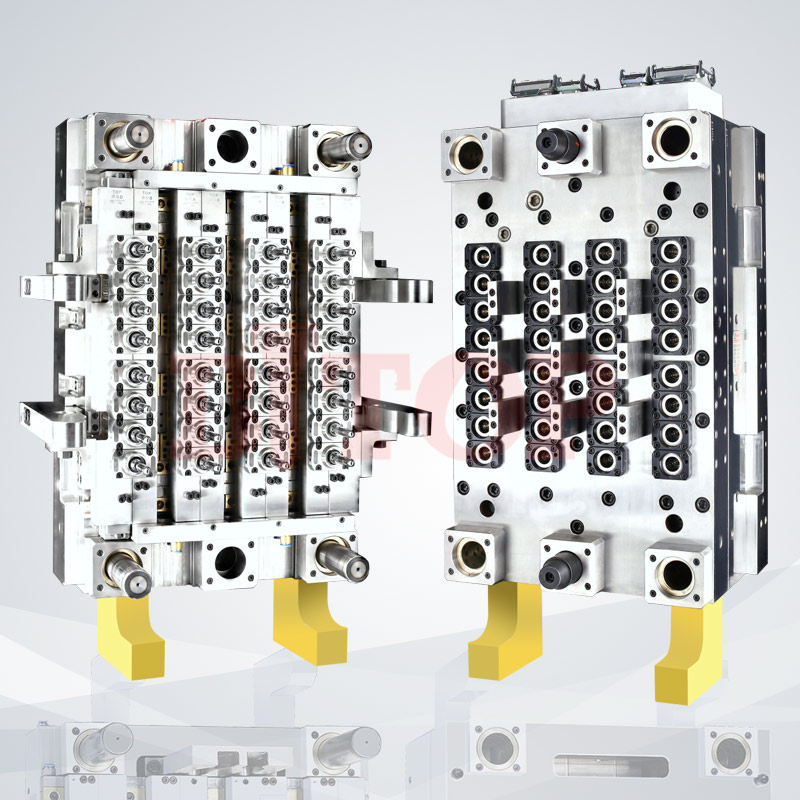

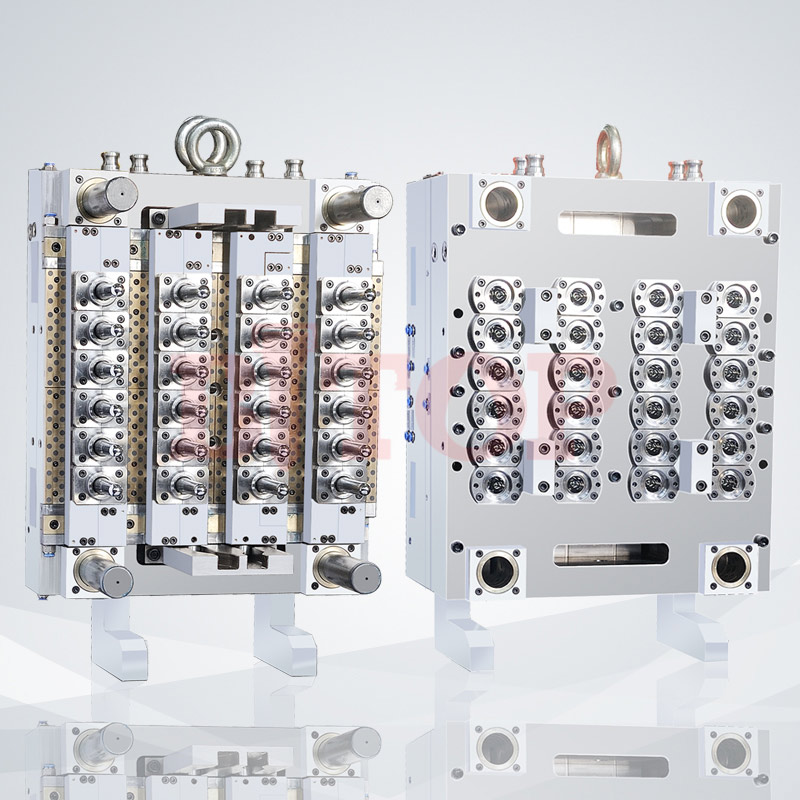

48cavity needle valve type hot runner preform injection mould

Our company is committed to producing high-quality preform molds, PET preform molds

Provide long gate, short gate and needle valve structure preform mold preform adopts computer simulation tensile test design to ensure the finished rate of blow molding. Using the world's advanced two-stage double taper positioning technology, each cavity is independently self-locking to ensure concentricity. The mold cavity and core are made of high-quality mirror-surface corrosion-resistant plastic mold steel, which has high hardness and long life. The threaded mouth is manufactured according to international standards, and imported nitriding steel is selected, which has high hardness and long life. The hot runner design is advanced, the nozzle temperature is controlled at a single point, and the heating temperature is uniform, which improves the quality of the preform. The excellent cooling system realizes the high efficiency of water cooling at room temperature and fully automatic production. Cut-free gates ensure fully automatic production of molds and reduce labor costs.

other:

1. The core, cavity, core plate, cavity plate, cylinder plate and wiring board have cooling systems to ensure a good cooling effect.

2. German-style PID temperature control box.

3. Mold life: 5 million mold times.